Pelletron Engineering

Pneumatic conveying technologies have changed over the years. In former times, dilute phase conveying systems have been installed in plastic manufacturing and compounding plants. This technology creates dust and streamers that were accepted in the past, but not today anymore. High quality demands for clean resins require upgrades of existing conveying and dedusting technologies. Pelletron can offer a wide variation of such new technologies for conveying, dedusting and components.

- Use STRANDPHASE® conveying to upgrade dilute phase or dense phase conveying.

- Eliminate or shut off elutriators and drum sieves and install modern dedusting systems.

- Replace long radius elbows with Pellbows

Our modern processes help to increase the capacity and reduce dust and streamers in a plant as well as saving of energy costs.

Pelletron Engineering Capabilities

- Complete System engineering and design of pneumatic conveying and DeDuster® systems

- Debottlenecking and Optimization Concepts for existing systems

- Equipment supply

- Electrical control systems

- Fundamental Conveying testing including attrition tests and fines analysis

- Turnkey Installation, Installation supervisions, start-up and training

Please let us know how we can optimize your process.

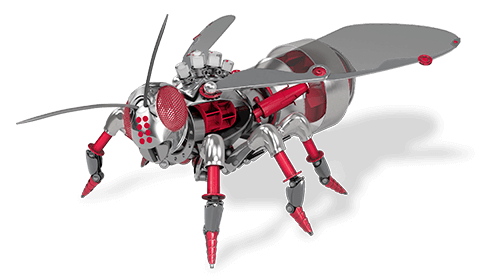

Bee clean. Bee efficient. Bee with us.