XP-Series DeDuster® Product Line

DeDuster® models XP180 to XP1500 can be equipped with an automated inlet deflector. The inlet deflectors distribute the material evenly over both wash decks and are designed to regulate the material flow or shut it down completly. This option eliminates the need for the installation of a seperate feeding device.

Note: Selection of the DeDuster® model depends on the bulk density of the product being cleaned, the shape of the pellets and the type and quantity of the fines.

XP-Series DeDuster® X-tra low height & energy consumption

| DeDuster® model | capacity range in lbs/h | capacity range in kg/h | height flange to flange in inch – in mm | ||||||||||

| XP15 | 1,000 | – | 3,500 | 500 | – | 1.500 | 24" | – | 600 | ||||

| XP45 | 3,500 | – | 11,000 | 1.500 | – | 5.000 | 33" | – | 840 | ||||

| XP90 | 11,000 | – | 22,000 | 5.000 | – | 10.000 | 33" | – | 840 | ||||

| XP180 | 22,000 | – | 45,000 | 10.000 | – | 20.000 | 40" | – | 1020 | ||||

| XP360 | 45,000 | – | 90,000 | 20.000 | – | 40.000 | 40" | – | 1020 | ||||

| XP540 | 90,000 | – | 130,000 | 40.000 | – | 60.000 | 58" | – | 1480 | ||||

| XP720 | 130,000 | – | 180,000 | 60.000 | – | 80.000 | 70" | – | 1780 | ||||

| XP900 | 180,000 | – | 210,000 | 80.000 | – | 95.000 | 70" | – | 1780 | ||||

| XP1080 | 210,000 | - | 240,000 | 95.000 | - | 110.000 | 75" | – | 1910 | ||||

| XP1500 | 240,000 | - | 330,000 | 110.000 | - | 150.000 | 75" | - | 1910 | ||||

Want to test your products?

Get Free-of-Charge dedusting test!

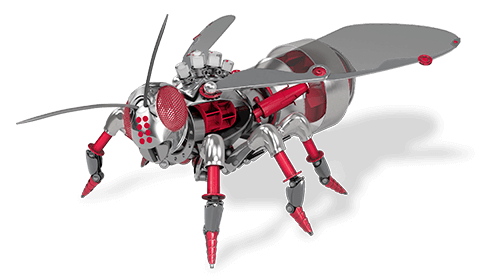

Bee clean. Bee efficient. Bee with us.